Electronic Manufacturing Surface Mount Technology Advancements

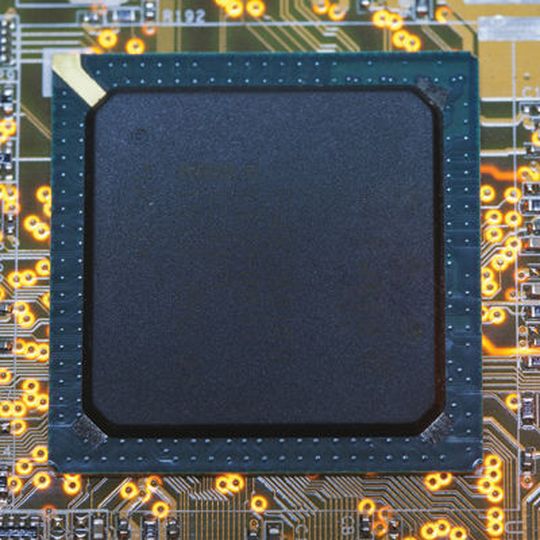

The impact on PCBs and PCBAs is the need for faster transmission speeds, smaller feature sizes and new technology. Engineers and designers recognise that advancements in PCBs and SMT require substantial time and investment. This article reviews some recent developments and challenges of SMT.

Anbieter zum Thema

Electronic manufacturing service (EMS) providers and OEMs are working to solve some key technology challenges such as: reducing the pitch between components whilst reserving sufficient space for rework, minimising voids in bottom termination components (BTCs), eliminating “head-on-pillow” (HOP) defects in connections and improving the robustness of PCBs used in high temperature and/or corrosive industrial environments such as oil and gas exploration. These issues continue to drive significant advances in SMT processes as the number of terminations increase and pad pitch decreases.

Continual evolution in surface mount technology (SMT) is driven by the introduction of new components to the market. In the early 1980s the 64-pin pin grid array was considered state of the art. BGA devices with up to 3700 terminations are in production today. This is a significant increase in complexity. 200 to 300 pins on bottom-terminated components (BTC) are not uncommon today. When they were introduced in the 1990s, pin counts of just a few dozen pins were typical. Pad pitch for devices in production today has been reduced to 0.4mm or less compared to between 1 mm and 1.5mm several years ago. Various factors drive pad pitch limitations, including PCB via pitch, via technology (e.g. stacked vias) and line pitch.

In addition to the need for higher densities and pin counts is the need for higher performance. Placing passive components as close as possible to an IC’s power and ground pins improves decoupling. Increasing speed and signal integrity drives PCB technology to minimise chip to chip spacing. Increasing performance at a lower cost drives demand for BTC. Today’s complex designs with increased functionality and higher speeds need closer IC and component spacing, complicating PCBA rework. These performance requirements drive the continuing advancement of SMT, processes and materials.

Here is a review of some SMT technology advances and a look ahead to the challenges.

(ID:43748779)

:quality(80)/p7i.vogel.de/wcms/95/31/95310c8d999f5f03b3af634a6e98c608/0129557153v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ce/09/ce09cbfd70dd50b7f8e9e923c4fd8f3d/0129481054v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/59/bf/59bfd2822d711b0ae2cb9383b679f38d/0129302533v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/27/e3/27e33398c34f4f466fe70a294ec2f1f1/0129569421v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ca/81/ca81333a02b8c934dcad5c1745435a3d/0125018126v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/06/ce/06cece1c695ea91c5108cf7f583feea5/0129540778v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3f/69/3f69e2ac28f7f9ee735680c5e5d53d94/0129470810v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7b/57/7b5725dd2e7545ab4904a9b7a3735721/0129309389v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/77/b1770e7d7499d7f807a2d5236dc081c8/0129461958v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2e/2a/2e2a5297d427998ec3f2afeaa44a4576/0129577028v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9d/f7/9df7b15f177b8b3ca0e93cf965a476bc/0129529705v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/e5/1de5e11918cfb261b8b5c4632fc1f7db/0129456364v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/e8/a8/e8a8a953c77af9bbf208cce6454139d4/0129427931v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/61/85/6185c7a5619aba866e3b237690bea839/0129334467v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/c7/f6/c7f61d0437c7f8fca3c6ff947ba2ad62/0129322490v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/0c/660c31afa35398bac9be42f2be73fdc4/0129073529v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9c/35/9c35ed04fa562b190cbc496a695a6802/0128823288v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/e6/d7e6fe4124ec2efc726e9c3f2c2a4cfc/0128241940v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/92/fd/92fd7c3102fc8b710244ad109c079be6/0129551381v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8f/bf/8fbf2cfa5f7238e41e046b12e936212b/0129541806v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/4f/fc4f36089dac773f0b9483eb39a726a1/0129508876v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/84/10/8410f7a52af344d1e5626d0610c9fa23/0129553240v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/bc/42/bc42dd0a04818f6195a7f78bcec88be6/0129484567v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/14/63/14635e09eff181f7ab7a0f81ffa0daa3/0129407664v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ff/e4/ffe44f0dcf0fc0323926b1bc0a60d94f/0129386849v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/95/24/952434ded60a1fc6dff2f7b742f14fd1/0129562074v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/00/f8/00f8ec6e6eb38a0fd8d66797394ef4d5/0129560475v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/62/1c/621cb1390951d6ac4029cd471edf956d/0129543495v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2c/60/2c60940d2ebd2d45765085bc69488764/0129530286v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/1f/691f39ba12be3cad90eb88bdabc456a6/0127321404v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6a/cc/6acc4f803241cfe5b6d60560c0a2b4d9/0126684948v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ef/aa/efaae5a25fb0a4c55c434611033447af/0126532350v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/9600/9682/65.jpg)

:quality(80)/p7i.vogel.de/wcms/7d/27/7d277a20a9ea7e17c226372c4d951316/0124246561v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ab/73/ab73d241611c109a242a4e5f1b50d01e/0128483827v4.jpeg)