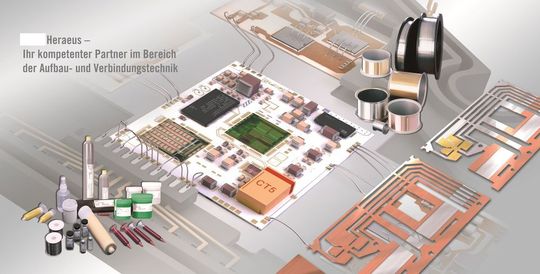

Heraeus Robust power electronics through improved mounting technologies

Improving power cycle performance is the goal of many power semiconductor experts. The materials used in integrated circuit and mounting technology comprise one key element.

Integrated circuit and mounting technology as we know it will change drastically – components are getting smaller all the time, while performance requirements are growing. Developers need to take into consideration the influence and significance of materials as the power density, switching frequency, and reliability specifications all increase. Ultimately, specifying the components and materials to be utilized is vital in order to ensure that devices function smoothly, for example at the high temperatures that arise through higher power densities.

In most standard power electronics modules, the circuit configuration is done through solder joints, such as bonding with thick-stranded aluminum wires. These days lead-free SnAg solder is used; SnPb/Ag was previously common. These materials and the corresponding processes have been used successfully for years.

Current trends in mounting technology

Now the power density is permanently increasing, combined with higher operating temperatures (150, 175, 200 °C and higher) and coupled with requirements for improved long-term reliability (more than 15 years for automotive applications). This takes the known integrated circuit and mounting materials to their very limits. The death blow is delivered for conventional mounting materials by high temperature peaks, for example when starting a cold car in winter or from rapid load changes in power electronics, which represent a particular challenge with regard to power cycle performance.

In the future, semiconductor materials such as SiC and GaN (silicon car-bide and gallium nitride respectively) will also be used in performance electronics. These semiconductors enable significantly faster switching frequencies, lower switching losses, and increased power densities – and will still function reliably at significantly higher junction temperatures. Due to its excellent heat conductivity and wide band gap, SiC is also very well-suited for higher performance categories, power densities, and junction temperatures. Consequently, there is a need for optimized mounting materials with improved mechanical, thermal, and electrical properties. Naturally, these new materials need to function reliably at higher operating temperatures.

The challenge of conflicting objectives

Heraeus, the technology company from Hanau, has worked on these is-sues in a number of projects, especially regarding the transition to lead-free solders with improved thermocyclic performance and the high-temperature properties of the solder alloys.

One typical challenge in these projects is the conflicting objectives of having the lowest possible process temperature for soldering (load on the components, circuit boards, etc.) and the desired high-temperature properties for the joints. Therefore, simply increasing the melting point is not effective. New innovations to emerge from this conflict of objectives include special alloys such as the 6-component system SnAgCuBiSbNi (Heraeus calls it InnoLot®) and the HT1 alloy (SnAgCuIn + crystal modifier).

Both new alloys have similar melting points to SnAg solder and enable better thermocyclic and high-temperature properties. At the power electronics module level, it further improves the maximum allowable operating temperature and the power cycle performance.

(ID:43634735)

:quality(80)/p7i.vogel.de/wcms/95/31/95310c8d999f5f03b3af634a6e98c608/0129557153v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ce/09/ce09cbfd70dd50b7f8e9e923c4fd8f3d/0129481054v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/59/bf/59bfd2822d711b0ae2cb9383b679f38d/0129302533v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/27/e3/27e33398c34f4f466fe70a294ec2f1f1/0129569421v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ca/81/ca81333a02b8c934dcad5c1745435a3d/0125018126v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/06/ce/06cece1c695ea91c5108cf7f583feea5/0129540778v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3f/69/3f69e2ac28f7f9ee735680c5e5d53d94/0129470810v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7b/57/7b5725dd2e7545ab4904a9b7a3735721/0129309389v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/77/b1770e7d7499d7f807a2d5236dc081c8/0129461958v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2e/2a/2e2a5297d427998ec3f2afeaa44a4576/0129577028v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9d/f7/9df7b15f177b8b3ca0e93cf965a476bc/0129529705v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/e5/1de5e11918cfb261b8b5c4632fc1f7db/0129456364v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/e8/a8/e8a8a953c77af9bbf208cce6454139d4/0129427931v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/61/85/6185c7a5619aba866e3b237690bea839/0129334467v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/c7/f6/c7f61d0437c7f8fca3c6ff947ba2ad62/0129322490v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/0c/660c31afa35398bac9be42f2be73fdc4/0129073529v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9c/35/9c35ed04fa562b190cbc496a695a6802/0128823288v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/e6/d7e6fe4124ec2efc726e9c3f2c2a4cfc/0128241940v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/92/fd/92fd7c3102fc8b710244ad109c079be6/0129551381v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8f/bf/8fbf2cfa5f7238e41e046b12e936212b/0129541806v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/4f/fc4f36089dac773f0b9483eb39a726a1/0129508876v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/84/10/8410f7a52af344d1e5626d0610c9fa23/0129553240v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/bc/42/bc42dd0a04818f6195a7f78bcec88be6/0129484567v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/14/63/14635e09eff181f7ab7a0f81ffa0daa3/0129407664v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ff/e4/ffe44f0dcf0fc0323926b1bc0a60d94f/0129386849v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/95/24/952434ded60a1fc6dff2f7b742f14fd1/0129562074v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/00/f8/00f8ec6e6eb38a0fd8d66797394ef4d5/0129560475v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/62/1c/621cb1390951d6ac4029cd471edf956d/0129543495v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2c/60/2c60940d2ebd2d45765085bc69488764/0129530286v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/1f/691f39ba12be3cad90eb88bdabc456a6/0127321404v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6a/cc/6acc4f803241cfe5b6d60560c0a2b4d9/0126684948v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ef/aa/efaae5a25fb0a4c55c434611033447af/0126532350v2.jpeg)

:quality(80)/images.vogel.de/vogelonline/bdb/946000/946018/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/946000/946015/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/946000/946016/original.jpg)

:quality(80)/images.vogel.de/vogelonline/bdb/946000/946017/original.jpg)

:quality(80)/p7i.vogel.de/wcms/da/e4/dae45caa7f4fa7125e17b07d9da016bb/0125786170v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ab/73/ab73d241611c109a242a4e5f1b50d01e/0128483827v4.jpeg)