Laser Direct Structuring LPKF Presents Prototyping for 3-D Molded Interconnect Devices

The LDS process has something to offer: thanks to laser direct structuring (LDS), traces are produced on three-dimensional plastic bodies. Instant metallization generates the copper strip conductors.

Anbieter zum Thema

Three-dimensional molded interconnect devices (MIDs) execute a whole series of tasks that require a compact design. A key use is for antenna structures on plastic components for space- and weight-sensitive smartphones and tablet computers. But LDS components have also proven to be economical and reliable as carriers for radar antennas, air pressure sensors, housings for sensor packaging, in hearing aids and in LED technology.

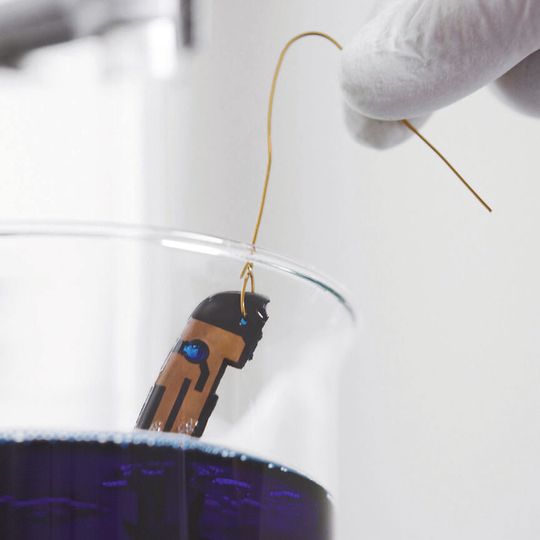

Components made of plastic to which an additive has been added serve as the basis for MIDs. A laser process exposes the additive and creates a micro-rough surface for better adhesion of the strip conductors. Then a currentless metallization bath builds up copper strip conductors on the milled areas. A finish with nickel and gold can then follow in the serial process.

How to produce the LDS prototypes

At the productronica 2013 (Hall B2, Booth 105), LPKF presents systems and products to produce LDS prototypes. They close the gap between design and serial production.

LDS prototyping uses a three-dimensional base body, such as a 3-D print. A sufficiently smooth surface is required. The printed base body is covered with LPKF ProtoPaint LDS, a paint in a spray can that contains LDS additives. A single thorough painting in cross-coat usually suffices for preparation.

LPKF is presenting a new laser system for laser structuring. It is based on the proven ProtoLasers and is equipped with an optimized laser source.

The LPKF ProtoLaser 3D requires only a socket outlet and an exhaust. It has a height-adjustable working platform. The working range is 300 x 300 x 50 millimeters and the scanning field is 100 x 100 x 25 millimeters. A highly developed vision system references the position of the components and strip conductors, and a pilot laser helps with setting up the jobs.

The metallization process is as easy as making coffee: The base metallization is poured into the beaker and is heated to the working temperature of ca. 44 °C. A pre-prepared activator subsequently starts the process. The components are then simply immersed in the bath. The copper layer can be built up to 10 µm. After metallization, the consumed bath chemicals are disposed of in the original canister.

* Malte Borges is PR manager for product communication at LPKF (www.lpkf.com).

(ID:42360948)

:quality(80)/p7i.vogel.de/wcms/59/bf/59bfd2822d711b0ae2cb9383b679f38d/0129302533v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c1/94/c19403fe0194686b2f4911be7e1e9539/0129294209v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e6/72/e67279e23a3267a463edf3e3f55c8e81/0129260553v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ee/4e/ee4edfc487a381146392072ab90dfc57/0129365186v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/c2/cdc2463f324033ec22c60e74d983241c/0129371522v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/5c/4f/5c4f0eb073c372e2a494f37dd6783458/0129341654v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7b/57/7b5725dd2e7545ab4904a9b7a3735721/0129309389v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b2/9c/b29ce10d1817d4b67968dfb737d812b7/0129308255v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ac/a9/aca924f5aeb2280243c679915eb60213/0129344939v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/28/0f/280fe550dfb032b53edbaac11d09bced/0129337134v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/61/85/6185c7a5619aba866e3b237690bea839/0129334467v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/88/3c8863ad57e80adc0acb9c9d9ea30351/0129319571v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4e/f2/4ef224fde728985d8b9630eb0fa37909/0129293948v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/c7/f6/c7f61d0437c7f8fca3c6ff947ba2ad62/0129322490v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/0c/660c31afa35398bac9be42f2be73fdc4/0129073529v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9c/35/9c35ed04fa562b190cbc496a695a6802/0128823288v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/e6/d7e6fe4124ec2efc726e9c3f2c2a4cfc/0128241940v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e6/0a/e60ae162bd38bfc111ecf434d5c5fbd7/0129308123v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/75/c0/75c0d5ccd1cee4e66dbd5f3ed02efd0a/0129305300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a7/8c/a78c5f851db209abb1540909918fbf4a/0129260768v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9a/51/9a5199a5ad49e895b4aef7e04fe629e2/0129255110v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d9/d6/d9d68c274ac9c3c728978fac46c773ba/0129239468v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ad/e0/ade04f51223e20c7a603098cb8e0e008/0129391530v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d3/8b/d38b428f9a0a53319b1a54772f308d32/0129368862v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/bc/fc/bcfc3182c6e2422b82a9d0e1ce7dd945/0129336204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2c/40/2c40cea54250c0cc97dbc8d8448798a5/0129385029v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d4/8e/d48e2d9c551ae29c91c25e2208f40608/0129384442v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c7/de/c7ded37e1a429fe2234da21e0c272a09/0129363486v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/89/6b/896bbee46d0440c8a01ce4d0dab325f0/0129302555v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/1f/691f39ba12be3cad90eb88bdabc456a6/0127321404v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6a/cc/6acc4f803241cfe5b6d60560c0a2b4d9/0126684948v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ef/aa/efaae5a25fb0a4c55c434611033447af/0126532350v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/10800/10894/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/93300/93330/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/9600/9682/65.jpg)

:quality(80)/p7i.vogel.de/wcms/da/e4/dae45caa7f4fa7125e17b07d9da016bb/0125786170v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7d/27/7d277a20a9ea7e17c226372c4d951316/0124246561v2.jpeg)