LED Technology Designing a Better Street Luminaire Heatsink with Thermal Simulation

High temperatures can reduce an LED’s light output and cause a color shift and, at the same time, shorten the component’s useful effective life. Heat dissipation design is a key factor in the performance of power LEDs.

Anbieter zum Thema

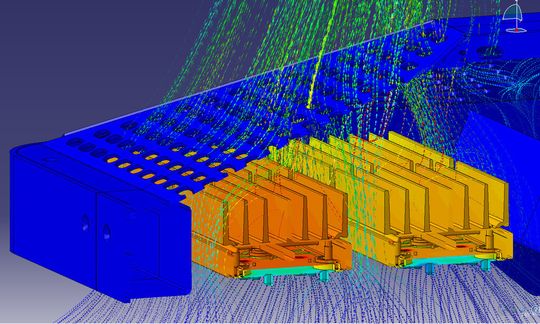

The thermal management of a street luminaire is particularly challenging because the ambient temperature changes depending on season and location. Finding the solution for thermal problems can take 80% of the time the team spends on designing a new product. During the design development phase of the street-light fixture, the R&D team started with the question “How can we solve the cooling of LED modules in the most efficient way?”Based on years of experience in designing heat transfer equipment, the answer was easy: take the heat away from the LED module, provide enough surface-to-heat dissipation, and provide good air flow.

But some questions weren’t so easy:

- What airflow is needed to take the heat away on 55° C ambient temperature from the 140 W power LED module?

- In what way can we provide the optimum heat dissipation surface?

- Where will the hottest air pockets be formed?

Optimizing the heatsink design empirically would require a lot of time and money. The R&D team decided to use software simulation and analyses to speed up the development time. The computational fluid dynamics (CFD) software they chose, FloEFD from Mentor Graphics, provides guidance and help so that engineers who are not CFD specialists can perform fluid flow, cooling, and other analyses as part of their design process and within their product design tool.

The software allows engineers to perform CFD—without the attention of a trained specialist—automatically. This automation means that product designers can try out a succession of ideas on a design without risking the project deadline, reducing simulation time compared to traditional CFD tools.

The CFD software also makes it relatively easy to conduct “what-if” tests. FloEFD helps create multiple variations of designs by modifying parametric CAD configurations, which can then be analyzed without having to reapply loads, boundary conditions, material properties, and the like. The engineer simply compares the results among the many design options to choose the best possible design.

The simulation software enables product designers as well as specialists to accelerate key decisions at their workstations as they experiment with design scenarios and as they hone in on the best, most efficient, reliable, and cost-effective design. This intuitive “virtual prototyping” process allows designers to optimize a product during the design stages, with that first physical prototype often being the design that goes into final manufacturing, delivering the best design at lower cost (because of fewer physical prototypes), and getting it to market faster than ever before.

(ID:42896286)

:quality(80)/p7i.vogel.de/wcms/59/bf/59bfd2822d711b0ae2cb9383b679f38d/0129302533v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c1/94/c19403fe0194686b2f4911be7e1e9539/0129294209v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e6/72/e67279e23a3267a463edf3e3f55c8e81/0129260553v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/5d/2b5d6ddedab3fdcaf528ff1caf650433/0129302953v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/89/6b/896bbee46d0440c8a01ce4d0dab325f0/0129302555v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7b/57/7b5725dd2e7545ab4904a9b7a3735721/0129309389v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b2/9c/b29ce10d1817d4b67968dfb737d812b7/0129308255v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4b/c5/4bc5a6e591592fac9c3f05b77b8c237f/0129307845v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/4c/f0/4cf066b46a5fcfc430a2454a5e82e801/0129279386v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/88/3c8863ad57e80adc0acb9c9d9ea30351/0129319571v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4e/f2/4ef224fde728985d8b9630eb0fa37909/0129293948v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/3f/0d/3f0d634d8c172031474c341b3a2b725e/0129262158v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c7/f6/c7f61d0437c7f8fca3c6ff947ba2ad62/0129322490v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/0c/660c31afa35398bac9be42f2be73fdc4/0129073529v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9c/35/9c35ed04fa562b190cbc496a695a6802/0128823288v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/e6/d7e6fe4124ec2efc726e9c3f2c2a4cfc/0128241940v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/75/c0/75c0d5ccd1cee4e66dbd5f3ed02efd0a/0129305300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/c1/9bc1caaaf2b30471c3d187069d2d8e4b/0129101585v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a7/8c/a78c5f851db209abb1540909918fbf4a/0129260768v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9a/51/9a5199a5ad49e895b4aef7e04fe629e2/0129255110v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d9/d6/d9d68c274ac9c3c728978fac46c773ba/0129239468v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/63/9e/639e76b1a5edc6cb79a45b63aefadcfd/0129234417v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0c/57/0c57cee9533d090c98061b4352d1103d/0129219561v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/1f/691f39ba12be3cad90eb88bdabc456a6/0127321404v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6a/cc/6acc4f803241cfe5b6d60560c0a2b4d9/0126684948v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ef/aa/efaae5a25fb0a4c55c434611033447af/0126532350v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/93300/93330/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/62/16/621651a93b1ef/logo-we-rgb-pos.png)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/111200/111228/65.jpg)

:quality(80)/p7i.vogel.de/wcms/7d/27/7d277a20a9ea7e17c226372c4d951316/0124246561v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3f/45/3f45b76aef06121a2016dd70cbecd5f3/0127037255v2.jpeg)