Relay applications note What should be considered in relay diagnosis

In many relay applications, it is necessary to diagnose the switching status of the relay contacts. Electromechanical relays differ in their switching performance of semiconductors, which must be taken into account in particular with regard to the contact resistance and switching times of diagnostic routines.

Anbieter zum Thema

Power relays were and are developed for switching and conducting electrical loads, e.g. lamps, motors and heating. These loads are usually operated with voltages of minimum 12 VDC or 120 VAC and generally require currents of at least 1 A. Diagnostic routines by contrast often work with signal levels, i.e. voltages below 12 V (e.g. 5V-TTL level) and currents in the milliampere range.

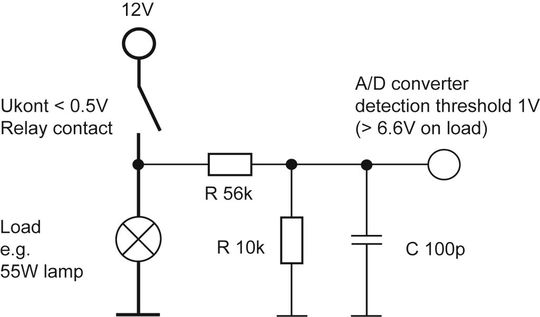

Power relays mainly use contacts made of silver alloys and compounds. Silver has the characteristic of reacting with the atmosphere and forming layers. These layers can lead to a contact voltage drop of up to 500 mV independent of the load current, which is usually unproblematic with load voltages of minimum 12 VDC. Since these layers also lead to non-linear contact resistances, it is inadmissible to conclude from a resistance measurement with small signal currents (e.g. a standard multimeter) the contact resistance in the actual loading case. An optimal diagnostic circuit therefore works with actual loading conditions and safe voltage thresholds.

Switching times

The switching times of electromechanical relays are dependent on different variable parameters. The operate time is influenced by the coil voltage, coil temperature and ageing of the relay over its service life. Voltages and temperatures can vary, especially in motor vehicles. As a result, the relay operate time under worst case conditions can be up to five times the typical operate time at nominal voltage and ambient temperature.

The release time depends largely on the coil circuit and relay ageing. A diode parallel to the coil can extend the release time as much as fourfold. Diagnostic routines are generally subject to time restrictions and have static program sequences, i.e. the scanning times are independent of voltages and temperatures. If the diagnostic software does not take the maximum possible switching times into account, this can lead to incorrect evaluations of the switching status.

Relay coils are frequently energized briefly or energization is interrupted briefly in order to monitor the continuity of the coil (so-called watchdog routines). To be taken into account is that the diagnostic impulse must not lead to a change in the contact condition. Due to the wide voltage and temperature ranges and ageing of the relay over its service life, the minimum relay switching times must be considered. These can deviate significantly from the typical switching times.

Recommendation

From the information in the data sheets and relay specifications, the parameters relevant for a diagnostic routine are often not recognisable, since the additional "Diagnostic" requirement is usually not taken into consideration for electromechanical components by the system developers.

It is essential to discuss this requirement with the experts of the relay supplier and make it an integral part of component specifications if necessary.

* Olaf Lorenz works as Application Engineer for TE Relay Products in Berlin.

(ID:42791248)

:quality(80)/p7i.vogel.de/wcms/59/bf/59bfd2822d711b0ae2cb9383b679f38d/0129302533v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c1/94/c19403fe0194686b2f4911be7e1e9539/0129294209v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e6/72/e67279e23a3267a463edf3e3f55c8e81/0129260553v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/5d/2b5d6ddedab3fdcaf528ff1caf650433/0129302953v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/89/6b/896bbee46d0440c8a01ce4d0dab325f0/0129302555v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7b/57/7b5725dd2e7545ab4904a9b7a3735721/0129309389v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b2/9c/b29ce10d1817d4b67968dfb737d812b7/0129308255v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4b/c5/4bc5a6e591592fac9c3f05b77b8c237f/0129307845v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/4c/f0/4cf066b46a5fcfc430a2454a5e82e801/0129279386v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/88/3c8863ad57e80adc0acb9c9d9ea30351/0129319571v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4e/f2/4ef224fde728985d8b9630eb0fa37909/0129293948v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/3f/0d/3f0d634d8c172031474c341b3a2b725e/0129262158v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c7/f6/c7f61d0437c7f8fca3c6ff947ba2ad62/0129322490v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/0c/660c31afa35398bac9be42f2be73fdc4/0129073529v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9c/35/9c35ed04fa562b190cbc496a695a6802/0128823288v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/e6/d7e6fe4124ec2efc726e9c3f2c2a4cfc/0128241940v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/75/c0/75c0d5ccd1cee4e66dbd5f3ed02efd0a/0129305300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/c1/9bc1caaaf2b30471c3d187069d2d8e4b/0129101585v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a7/8c/a78c5f851db209abb1540909918fbf4a/0129260768v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9a/51/9a5199a5ad49e895b4aef7e04fe629e2/0129255110v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d9/d6/d9d68c274ac9c3c728978fac46c773ba/0129239468v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/63/9e/639e76b1a5edc6cb79a45b63aefadcfd/0129234417v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/0c/57/0c57cee9533d090c98061b4352d1103d/0129219561v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/1f/691f39ba12be3cad90eb88bdabc456a6/0127321404v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6a/cc/6acc4f803241cfe5b6d60560c0a2b4d9/0126684948v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ef/aa/efaae5a25fb0a4c55c434611033447af/0126532350v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/130400/130457/65.jpg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/72000/72046/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/5f/f7/5ff7108437e0a/logo-20190211-02.jpg)

:quality(80)/p7i.vogel.de/wcms/da/e4/dae45caa7f4fa7125e17b07d9da016bb/0125786170v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7d/27/7d277a20a9ea7e17c226372c4d951316/0124246561v2.jpeg)