Measuring High Voltage Lifetime of Digital Isolators

Analog Devices guarantees the working voltage of our iCoupler digital isolators with testing other than partial discharge. iCoupler digital isolators use 20 μm thick polyimide insulating layers between planer transformer coils that are part of the wafer fabrication process (see figure 1).

This manufacturing process allows for the isolation elements to be integrated with any foundry semiconductor process at low cost and with excellent quality and reliability. The cross section below shows the turns of the top and bottom coils separated by the thick polyimide layer. Polyimide materials have been used for insulation for many years; nearly one billion iCoupler transformers have been manufactured and used reliably for over ten years.

To measure the working voltage lifetime of these chip-scale isolation transformers, we employ a High Voltage Endurance (HVE) setup. HVE is done through time to failure experiments at accelerated voltage levels, usually much higher than the specified working voltages.

Charge injection is the primary HVE failure mechanism that causes isolation breakdown in iCoupler devices. After charges are injected into the polyimide insulation, they may be trapped in local trap sites where they release energy. If the released energy is high enough, bonds within the polyimide will break, thereby creating more trap sites that will lead to more space charge trapping. This positive feedback eventually leads to insulation breakdown.

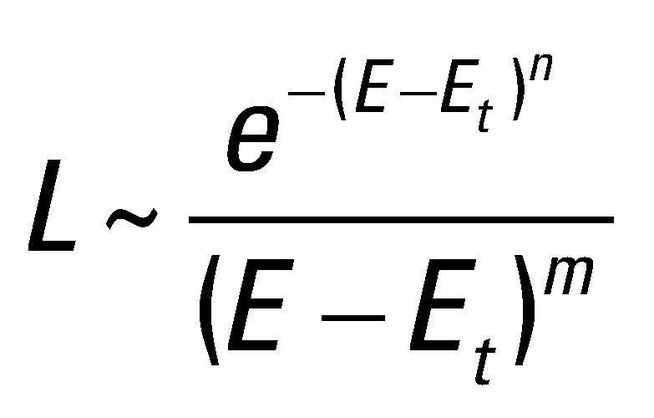

Through thermodynamic analysis [1], the lifetime L can be expressed as,

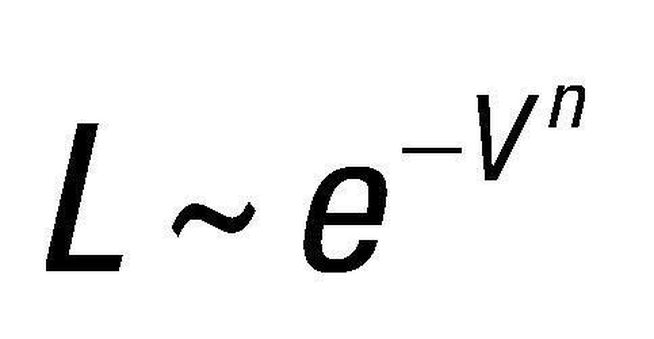

where Et is the threshold field where no charge injection will happen, and m, n are scaling constants. HVE data from iCoupler devices has been observed to follow,

Where L is the time to failure at 10 ppm, V is the applied, continuous high voltage.

Figure 2 shows a simplified example where four data points from high voltage stressing samples are used to fit the model and extrapolate back to typical working voltages.

This data was measured by subjecting samples to 60 Hz common-mode potential differences from 800 to 2,000 Vrms. Time-to-failure for each unit was recorded summarized in the Weibull plot below. Time-to-failure was extrapolated for lower voltages within the intended working voltage range.

iCoupler HVE lifetime depends on whether the applied voltage is AC or DC. Under DC stress, the static field inhibits the trap/recombination release of energy. As a result, DC lifetimes are considerably longer than AC lifetimes. iCoupler products always specify the worst-case AC lifetime.

The “rms” specification of working voltages is also somewhat misleading. A 400 Vrms waveform is actually a sinusoid switching between positive 560 V and negative 560 V, so the full peak-to-peak stress across the barrier is actually 1,120 V. We have confirmed that the lifetime for a bipolar waveform specified at 400 Vrms is the same as a 1,120 V peak-to-peak waveform, independent of where it is centered. Data sheets where safety is critical should be conservative to ensure no potential hazards, which is why data sheets for iCoupler digital isolators that use polyimide insulation specify the absolute worst-case working voltage.

Digital isolator suppliers must complement the standards

The introduction of digital isolators has made an already complicated puzzle of safety standards even more confusing because not all standards address requirements for digital isolators which use different materials and elements for galvanic isolation. For lifetime under certain working voltage conditions, certification based on partial discharge is not sufficient to guarantee reliably safe operation over decades of use, as is the case with optocouplers.

New standards are being written to address this shortcoming, but until then digital isolator suppliers must complement these standards with reliable data to support claims of decades-long reliability.

iCoupler digital isolators based on polyimide insulation have done this and can guarantee more than 50 years of safe operation at rated working voltages using an accelerated life test.

Bibliography:

[1] L. A. Dissado, et al, “The incorporation of space charge degradation in the life model for electrical insulating amterials,” IEEE Trans. On Dielectrics and Electrical Insulation, Vol. 2, No. 6, pp 147-1158, December, 1995.

* * David Krakauer... is the product line manager for the Digital Isolator Group at Analog Devices in Norwood, U.S.A.

(ID:36003410)

:quality(80)/p7i.vogel.de/wcms/ce/09/ce09cbfd70dd50b7f8e9e923c4fd8f3d/0129481054v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/59/bf/59bfd2822d711b0ae2cb9383b679f38d/0129302533v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c1/94/c19403fe0194686b2f4911be7e1e9539/0129294209v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ca/81/ca81333a02b8c934dcad5c1745435a3d/0125018126v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/06/ce/06cece1c695ea91c5108cf7f583feea5/0129540778v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/79/33/7933c5529f1bbc132e7935d7c53b6beb/0129501631v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/3f/69/3f69e2ac28f7f9ee735680c5e5d53d94/0129470810v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7b/57/7b5725dd2e7545ab4904a9b7a3735721/0129309389v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b1/77/b1770e7d7499d7f807a2d5236dc081c8/0129461958v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9d/f7/9df7b15f177b8b3ca0e93cf965a476bc/0129529705v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/3f/673f67f2c8dbef2f0f6a5d01ec1f5ec6/0129505643v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/1d/e5/1de5e11918cfb261b8b5c4632fc1f7db/0129456364v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/e8/a8/e8a8a953c77af9bbf208cce6454139d4/0129427931v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/61/85/6185c7a5619aba866e3b237690bea839/0129334467v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/c7/f6/c7f61d0437c7f8fca3c6ff947ba2ad62/0129322490v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/0c/660c31afa35398bac9be42f2be73fdc4/0129073529v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9c/35/9c35ed04fa562b190cbc496a695a6802/0128823288v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/e6/d7e6fe4124ec2efc726e9c3f2c2a4cfc/0128241940v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/8f/bf/8fbf2cfa5f7238e41e046b12e936212b/0129541806v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/fc/4f/fc4f36089dac773f0b9483eb39a726a1/0129508876v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/bc/42/bc42dd0a04818f6195a7f78bcec88be6/0129484567v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/14/63/14635e09eff181f7ab7a0f81ffa0daa3/0129407664v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ff/e4/ffe44f0dcf0fc0323926b1bc0a60d94f/0129386849v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a7/8c/a78c5f851db209abb1540909918fbf4a/0129260768v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/38/1d/381de324bbe6d190a95169372a8ca02b/0129540692v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/87/4e/874eb8316b30d4b79793576f26c7dc62/0129542275v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/62/1c/621cb1390951d6ac4029cd471edf956d/0129543495v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2c/60/2c60940d2ebd2d45765085bc69488764/0129530286v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a6/a8/a6a880c57faa551baeca28d4178de438/0129419457v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/1f/691f39ba12be3cad90eb88bdabc456a6/0127321404v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6a/cc/6acc4f803241cfe5b6d60560c0a2b4d9/0126684948v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ef/aa/efaae5a25fb0a4c55c434611033447af/0126532350v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ab/73/ab73d241611c109a242a4e5f1b50d01e/0128483827v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/da/e4/dae45caa7f4fa7125e17b07d9da016bb/0125786170v2.jpeg)