Anbieter zum Thema

DFM and DFFA – Design for Manufacturing and Final Assembly

With just a few DFM layout rules, there are tremendous improvements for the subsequent soldering process with the placement of the elements on a new circuit board design. Even the unassembled circuit board can achieve improved thermal/mechanical stability and process sturdiness with well-balanced copper distribution, particularly in flat power supply and GND locations.

In addition, optimized pad geometries also allow a very stable soldering process in terms of the soldering quality and maintaining the position. Alongside the functional constraints and specifications for component placement, the transport device and heat current of the reflow oven in the layout must be taken into account. When positioning, shading from high components or heat traps should be avoided as much as possible with massive components.

Device installation of different components into a housing continues to be primarily a manual process for small to larger counts. Here small improvements in the manual installation process already have a positive effect on the installation quality, installation time and thereby also production costs. As is the case for all DFX disciplines, also here early coordination and collaboration in product development and among installation specialists with a close relationship with the product are in demand.

Based on checklists and extensive experience and creative ideas, the number of required steps, tools, installations materials as well as the duration of the installation can be analyzed even in advance, and optimization possibilities for the product design can be suggested. Examples of this include having uniform screw types with the lowest possible number and thereby the ability to reduce the number of tool changes. Alternatives such as snap-in housing designs, which securely protect the electronics system without any screws would be another point on a checklist.

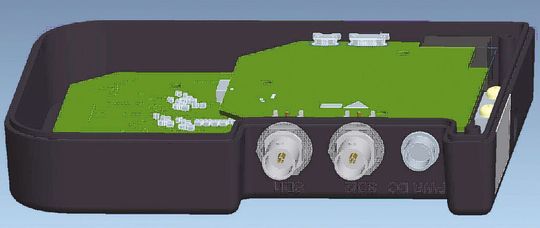

The contrast of two housing solutions serves as an example here. In the initial design (Fig. 2), the right assembly must be "threaded in" diagonally from the top through the recesses of the housing wall in the foreground. Depending on the skill level and sensitivity, faulty clamping can result during the insertion process.

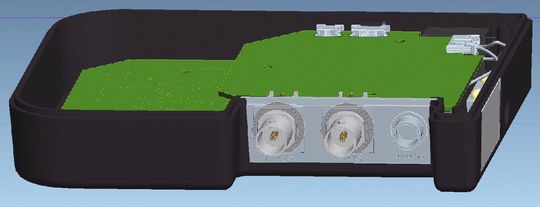

In comparison, the DFFA detail solution in Fig. 3 eliminates possible tensions with a separate cover element (highlighted in grey) because the assembly can be executed outside and freely. This offers the additional benefit of also being able to use the housing for other interface configurations without other cover inserts.

All boils down to cost: DFC – Design for Cost

In order to support competitive market prices right in the development phase, the Design for Cost rules prescribe a type of to-do list. When selecting components, here long-term supply security plays an important role in order to avoid frequent redesign cycles based on component discontinuations. The bundling or standardization of component types and values, along with the focus on less suppliers or manufacturers provide a considerable module for cost savings.

If the functionality of the product should allow the use of previously introduced and stable components and technologies, this guarantees a high level of stability and contributes to a product which is optimum and which can be produced with high quality. A further guarantee of long-term availability of the product in terms of production and repair is a long-term and functioning obsolescence management which, depending on the form, guarantees availability of key components beyond the standard service life of components.

Summary: DFX is an extensive tool kit

With a wide number of disciplines, DFX provides an extensive tool kit of design rules and checklists that can facilitate the ability to find a solution for process and product improvements. These rules can currently be applied to many industries and are not limited to those of the electronics area. The companies of the TQ Group, including SRI Radio Systems, have many years of experience with DFX methods. These methods could be implemented successfully in various projects of different industries. //FG

* Andreas Peter works since 1997 at SRI in the test engineering/testing tool development division, for which he has been the manager for several years.

(ID:42360938)

:quality(80)/p7i.vogel.de/wcms/59/bf/59bfd2822d711b0ae2cb9383b679f38d/0129302533v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/c1/94/c19403fe0194686b2f4911be7e1e9539/0129294209v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e6/72/e67279e23a3267a463edf3e3f55c8e81/0129260553v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/28/0f/280fe550dfb032b53edbaac11d09bced/0129337134v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/29/21/29218000af0daabca33bf8a7947b61ad/0129310204v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/5d/2b5d6ddedab3fdcaf528ff1caf650433/0129302953v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/7b/57/7b5725dd2e7545ab4904a9b7a3735721/0129309389v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/b2/9c/b29ce10d1817d4b67968dfb737d812b7/0129308255v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4b/c5/4bc5a6e591592fac9c3f05b77b8c237f/0129307845v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/61/85/6185c7a5619aba866e3b237690bea839/0129334467v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/3c/88/3c8863ad57e80adc0acb9c9d9ea30351/0129319571v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/4e/f2/4ef224fde728985d8b9630eb0fa37909/0129293948v3.jpeg)

:quality(80)/p7i.vogel.de/wcms/c7/f6/c7f61d0437c7f8fca3c6ff947ba2ad62/0129322490v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/66/0c/660c31afa35398bac9be42f2be73fdc4/0129073529v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9c/35/9c35ed04fa562b190cbc496a695a6802/0128823288v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d7/e6/d7e6fe4124ec2efc726e9c3f2c2a4cfc/0128241940v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/e6/0a/e60ae162bd38bfc111ecf434d5c5fbd7/0129308123v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/75/c0/75c0d5ccd1cee4e66dbd5f3ed02efd0a/0129305300v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/a7/8c/a78c5f851db209abb1540909918fbf4a/0129260768v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/9a/51/9a5199a5ad49e895b4aef7e04fe629e2/0129255110v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/d9/d6/d9d68c274ac9c3c728978fac46c773ba/0129239468v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/7a/527ad5ae7d10b9e34b72570639d7870c/plagiarius-zwerg-gnome-2849x1602v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/43/43/4343a389b15f84f683b7d1cdb4745d23/0129331527v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/89/6b/896bbee46d0440c8a01ce4d0dab325f0/0129302555v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/69/1f/691f39ba12be3cad90eb88bdabc456a6/0127321404v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/6a/cc/6acc4f803241cfe5b6d60560c0a2b4d9/0126684948v2.jpeg)

:quality(80)/p7i.vogel.de/wcms/ef/aa/efaae5a25fb0a4c55c434611033447af/0126532350v2.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/130400/130457/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/5f/88/5f8847c90d2e4/50-mm.jpg)

:fill(fff,0)/p7i.vogel.de/companies/5f/f7/5ff7108437e0a/logo-20190211-02.jpg)

:quality(80)/p7i.vogel.de/wcms/ab/73/ab73d241611c109a242a4e5f1b50d01e/0128483827v4.jpeg)

:quality(80)/p7i.vogel.de/wcms/7d/27/7d277a20a9ea7e17c226372c4d951316/0124246561v2.jpeg)